For the past eight years we have used Liquid Bearings synthetic lubricant here at oorail. While its not the cheapest product, its a multi-purpose 100% synthetic lubricant that is engineered for both high and low temperature applications. It is plastic safe and doesn't collect dirt, dust or debris like traditional petroleum based oils like 3-in-1. We have hundreds of locomotives here from the latest Hornby, Bachmann, Heljan, Dapol, Rapido Trains, Kato, DJ Models (now defunct), Tri-ang and many others. Many of our locomotives are brand new, while others are over 70 years old. We have never had a single problem with Liquid Bearings.

Due to the fleet we have here at oorail, it is not uncommon for locomotives to run every 6-8 months or so. So our standard practice is to overhaul a locomotive before running it on the track. This doesn't always mean it needs lubrication, but we will assess the situation. We are currently on our second 1.0 fl oz bottle of Liquid Bearings. We've only used about 10% of the second bottle so far, and we only used about 60% of the first bottle. We left the first bottle open for a few weeks and the oil turned a darker colour. While it seems fine, we use it for some of our older locomotives.

Whether its on the forums, facebook groups or another YouTube channel, every now and then someone asks if its safe to run 3-in-1 or lighter fluid or some other lubricant on their locomotives. This typically starts a debate and sometimes what borderlines on a holy war between those who have used 3-in-1 for decades and those who have embraced newer options. Nobody is actually wrong, the right answer is both yes and no.

When Should You Lubricate?

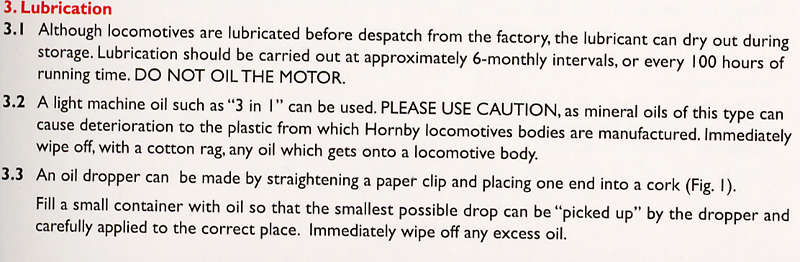

The general consensus between all of the manufacturers seems to be that every 6 months or every 100 hours of running. Locomotives that have sat in storage for awhile should be examined and lubricated if necessary. Not all motors should be lubricated. For example, Hornby have a number of locomotives where the service sheet advises NOT to lubricate the motor. So its best to consult the instructions for your specific locomotive to make sure there are no special instructions.

What Should You Lubricate?

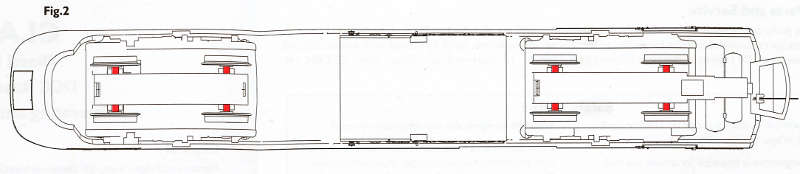

At a minimum you will want to lubricate anything that comes in contact with something else that moves. Typically this would include things like the axles, pistons / connecting rods on steam locomotives, and in some cases the NEM pocket/coupling depending on the locomotive. Hornby and most other manufacturers do a good job of highlighting lubrication points in the service sheets included with your model. For Hornby, these are typically highlighted in red.

Plastic Compatible Lubricant

Some manufacturers such as Bachmann and Heljan recommend a plastic compatible light oil or lubricant. What does this mean? This is the manufacturers way to off-load any liability onto the consumer. They're basically telling you to use an oil that is safe for plastics. They are leaving it up to you to make the right choice without actually offering any suggestions. Therefore, if you make the wrong decision and damage the locomotive, they don't necessarily need to honor the warranty.

To be brutally honest, if you've ever purchase second hand locomotives from eBay, you'll have a reasonable level of sympathy for why they've taken this approach. Not all synthetic oil is plastic compatible. For example, some motor oil is partially synthetic, so there is no guarantee that the additives in it are safe for the plastics used in your model locomotive. So far, we have found that Liquid Bearings and other 100% synthetic lubricants designed or marketed for model use, seem to be safe for the plastics used in model trains.

Is 3-in-1 (mineral oil) plastic compatible?

Hornby doesn't think so. For several decades now, Hornby has had statements such as

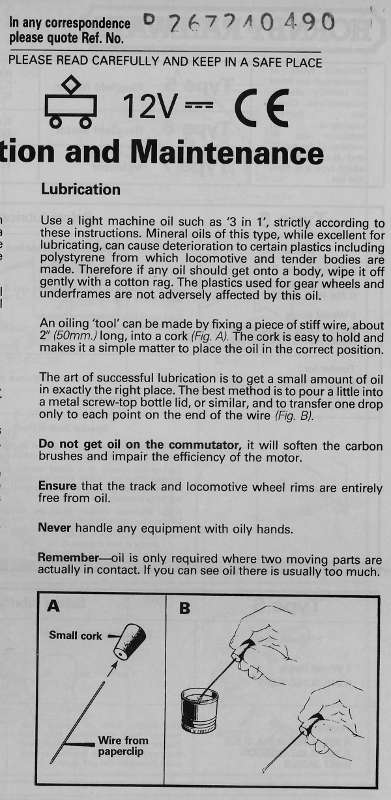

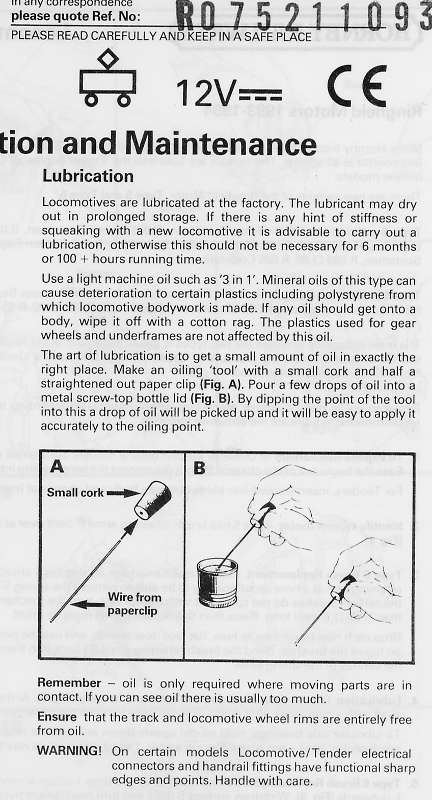

Use a light machine oil such as '3 in 1', strictly according to these instructions. Mineral oils of this type, while excellent for lubricating, can cause deterioration to certain plastics including polystyrene from which locomotive and tender bodies are made. Therefore if any oil should get onto a body, wipe it off gently with a cotton rag. The plastics used for gear wheels and underframes are not adversely affected by this oil.

Similar wording can be found in recent Hornby products, including the Hornby Pendolino Train sets from a few years ago. More recent Hornby products have replaced mentioning '3 in 1' and instead use the phrase light machine oil which is vague enough that it could mean anything from 3 in 1 to sewing machine oil to synthetic lubricant. Does this mean that more recent Hornby locomotives are made from a different type of plastic or are they simply offsetting their liability by no longer mentioning 3-in-1. Like other manufacturers have they passed the risk on to you the consumer?

Worth the risk?

Ultimately it comes down to a matter of risk. Are you willing to take the risk that you might accidentally transfer some 3-in-1 from the locomotive chassis to the body shell? The obvious selling point to using something like 3-in-1 is that its a much bigger bottle for a lot less money. On the other side of that argument though is that you use a minute amount of oil, the Hornby instructions from the 1990s for example tell you if you can see the oil, then you've used too much. So a tiny bottle of specialized locomotive oil is likely going to last you years if not longer. So is it really worth the risk damaging an expensive locomotive(s) for a very small amount of savings? That is going to come down to a personal choice, for me, it doesn't make any sense to take that risk. Murphy's Law will typically bite me if I did anyway.

When its not a choice?

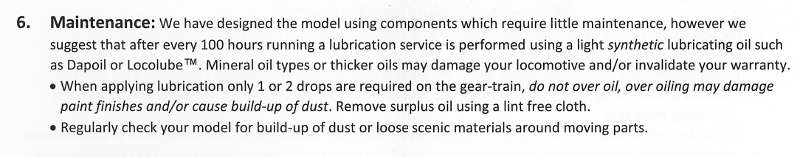

There are some manufacturers where its not an option to use mineral oil. Newer Dapol models specifically have wording that require you to use light synthetic lubricating oil such as Dapoil or LocolubeTM . The skeptics among us though might point fingers at Dapol's requirement and suggest that its a sales ploy to shift a few more cases of Dapoil. The manufacturers are producing much more detailed and advanced models compared to those even just a decade ago. It actually makes sense that thicker (aka. heavier) oils such as mineral oil, could provide enough friction or natural resistance that the motors have to work a lot harder than they are designed for. In a way, the manufacturers have moved towards low maintenance products, not just for our convenience but to reduce their support and warranty costs. If a consumer doesn't have to open or maintain the loco during the lifetime of the warranty, there is a much lower risk that they will mess something up and then request a warranty repair.

Historical Evidence

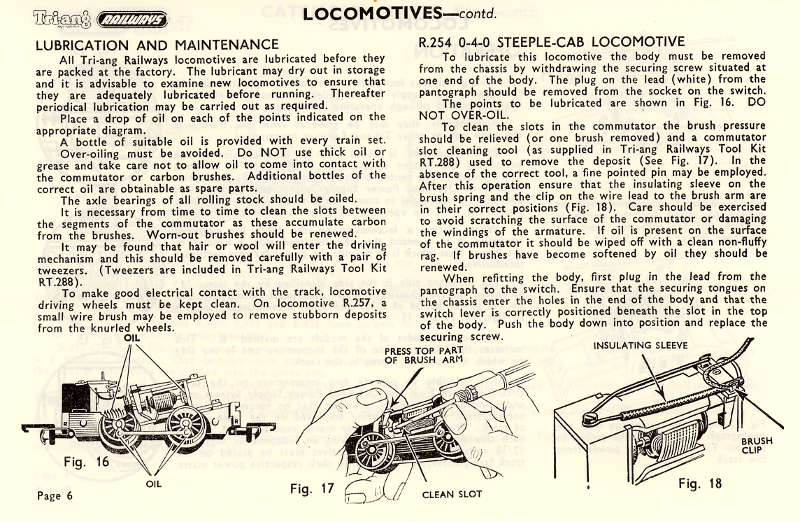

Tri-ang Railways used to supply a bottle of suitable oil with every train set. This oil could be obtained as spare parts from Tri-ang. Back in the 1950s and 1960s, the focus was on making the consumer as independent as possible in terms of maintenance and repairs. The servicing scheme from 1963 for example has wording that states Before taking a locomotive or other component to an Official Service Dealer or returning it for attention to a factory the owner should ensure that he personally cannot make the necessary adjustments. aside from the obviously non-PC use of he instead of they, its quite clear that Tri-ang wants the consumer to do whatever they can before resorting to returning the locomotive. Obviously a costly process on low-margin products in the 1960s, so the manufacturers had some incentive to make the products as serviceable as possible and encouraged giving it a go to repair it. Something that has been somewhat lost in today's society, but definitely something that could be reinstated with some encouragement from the Model Railway community.

If you watch the video above, you'll see a number of examples where Hornby are the clear source of the information that Mineral oils of this type, while excellent for lubricating, can cause deterioration to certain plastics including polystyrene from which locomotive and tender bodies are made. So the so called myth that 3-in-1 will melt your locomotive actually has some truth behind it, but its been exaggerated over the years, perhaps as fathers or grandfathers have issued a word of warning to their respective (grand) children to prevent costly mistakes, that has continued on through to adulthood. As you can see from my Wrenn Esso tank engine, mineral oils like 3-in-1, can definitely damage a locomotive body shell. Will it melt the locomotive? Probably note. Will it leave it in a less than pristine state? A very good possibility. It might not show up after a few hours, but if the mineral oil manages to permeate the plastic body shell, the damage can show up later on. So is it really worth the risk?

Plastic Compatible Synthetic Lubricant works for everything?

So the plastic compatible synthetic lubricant, whether its Dapoil or Liquid Bearings or some other product, will work for both your highly detailed Dapol Class 68 model as well as your 56 year old Tri-ang CKD Class 77. So why take the risk of making a mistake or accidentally transferring some 3-in-1 to the crystal clear finish on your Hornby King Steam Locomotive?

Debunking the Skeptics

So there is a rather entertaining YouTube video that claims to be Myth busting the use of 3-in-1 oil. They actually go as far as spraying an old Hornby shunter with a heavy amount of 3-in-1 before spraying it with WD-40. They take their antics a step further by emptying the contents of their hoover (vacuum cleaner for those who use Railroad instead of Railway) into a bag and tossing the loco chassis around in it like an angry Gordon Ramsey tossing chicken wings in marinade. They go one then to clean the wheels with kitchen towel before running it for an hour, making the claim that this somehow proves that 3-in-1 is safe.

The problem with this approach is that they tested the parts that Hornby quite clearly tell you are "not adversely affected by this oil". Hornby state that "The plastics used for gear wheels and underframes are not adversely affected by this oil". They tested the parts that aren't going to be damaged, then claim its safe to use. Whoops!

Part of the risk with using 3-in-1 or WD-40 for that matter on your locomotive, is that you'll accidentally use too much (easily done), it will get on your wheels and onto your track, then you'll be left with a right mess to clean up. The lads over at Budget Model Railways wiped the excess from the wheels and around the wheels before running their test.

Probably the most interesting thing though is that WD-40 is often used to clean parts, it can be used to spray down grimy and oily car parts for example, its designed to free up grime, oil and debris from stuck parts to loosen them. So whats surprising in their video is that they apply the 3-in-1 oil quite excessively but then immediately clean it up with WD-40. The WD-40 has essentially broken down the bulk of the 3-in-1. So you're not really testing if 3-in-1 is safe now are you?

They even followed things up with this cute bear video showing the chassis running after being a year in a drawer. The thing is, we have locomotives here that have sat in storage for several years, we can pick them up and they'll run without any issues. Leaving the underframe and gear parts that are not affected by 3-in-1 watered down by WD-40 (or quite possibly completely removed), doesn't really show anything. It just confirms what Hornby have already told you in the instruction sheet.

The problem these types of videos create is that they are not well researched and feed into the misinformation. I'm sure countless individuals who use 3-in-1 used this video to win their on-line arguments. Its too bad people can't do a quick bit of RTFM and avoid making a warranty voiding mistake.

Hopefully this video and the short bit of research we did will finally help put this debate to rest. The risk-adverse option is to use a synthetic model safe lubricant such as Liquid Bearings or Dapoil as this is the safe option for all your model locomotives. On the other hand, if you prefer to continue the long standing tradition of mineral oil and can avoid putting it on the wrong loco, its your model railway, do what makes you happy. Just don't hand out misleading advice to others when it could damage their trains!

Links to Lubricant Products

Here are a list of products that are worth checking out, the person who recommended them has their name beside the link.

- Liquid Bearings (Recommended by oorail.co.uk)

- Peco Electrolube (Recommended by David Tuckley)

- Dapoil (Recommended by Dapol)

- Gaugemaster GM619

Your Thoughts?

Let us know what you think? Watch the video above and feel free to comment on the video using YouTube.

Comments